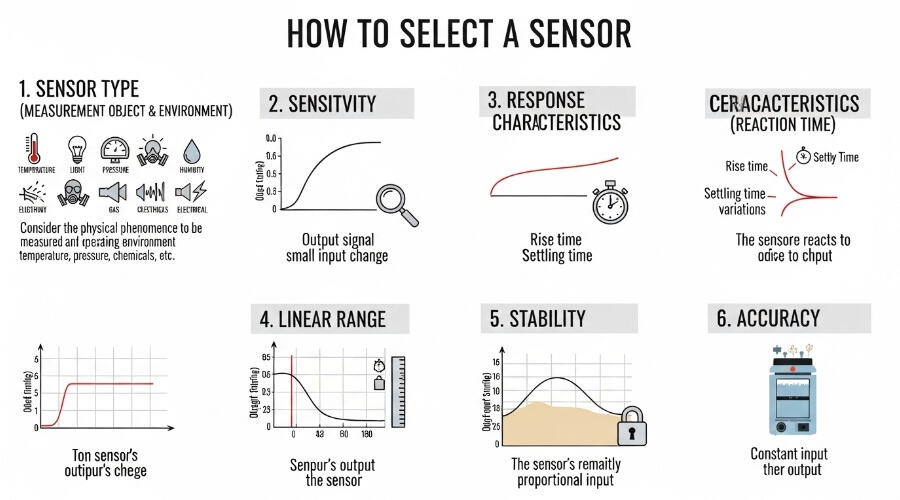

เซนเซอร์สมัยใหม่มีความหลากหลายอย่างมากทั้งในหลักการทำงานและโครงสร้าง การเลือกใช้เซนเซอร์อย่างเหมาะสมตามวัตถุประสงค์ สิ่งที่ต้องวัด และสภาพแวดล้อมการวัดเฉพาะเจาะจง คือปัญหาแรกที่ต้องแก้ไขเมื่อทำการวัดปริมาณใดๆ หลังจากที่กำหนดเซนเซอร์ได้แล้ว วิธีการวัดและอุปกรณ์ประกอบต่างๆ ก็สามารถระบุได้เช่นกัน ความสำเร็จของผลการวัดขึ้นอยู่กับการเลือกใช้เซนเซอร์อย่างเหมาะสมเป็นส่วนใหญ่

ขั้นแรก พิจารณา หลักการทำงาน การ ประเภทของเซนเซอร์ขึ้นอยู่กับวัตถุและสภาพแวดล้อมที่วัด

ในการดำเนินการวัดเฉพาะอย่าง ขั้นตอนแรกคือพิจารณาว่าจะใช้เซนเซอร์ตามหลักการใด ซึ่งต้องวิเคราะห์ปัจจัยหลายประการ แม้แต่ในการวัดปริมาณทางกายภาพชนิดเดียวกัน ก็มีหลายหลักการทำงานของเซนเซอร์ให้เลือก ความเหมาะสมของหลักการทำงานเซนเซอร์ขึ้นอยู่กับลักษณะของสิ่งที่ต้องการวัดและเงื่อนไขการใช้งานของเซนเซอร์ ซึ่งต้องพิจารณาประเด็นเฉพาะต่อไปนี้: m ช่วงการวัด เรา ข้อกำหนดเกี่ยวกับขนาดของเซนเซอร์ตามตำแหน่งที่ต้องวัด , c วิธีการวัดแบบสัมผัสหรือไม่สัมผัส , s วิธีการส่งสัญญาณออก (แบบมีสายหรือแบบไร้สัมผัส) , s ต้นกำเนิดของเซนเซอร์ (ในประเทศหรือนำเข้า) ความคุ้มค่าด้านต้นทุน หรือการพัฒนาเอง . หลังจากพิจารณาปัจจัยข้างต้นแล้ว สามารถกำหนดประเภทของเซนเซอร์ได้ จากนั้นจึงพิจารณาตัวชี้วัดประสิทธิภาพเฉพาะเจาะจง

สอง, การเลือกความไว . ทั่วไปแล้ว ในช่วงเชิงเส้นของเซนเซอร์ ความไวสูงเป็นที่ต้องการ การมีความไวสูงจะทำให้ได้สัญญาณเอาต์พุตที่ใหญ่ขึ้นเมื่อมีการเปลี่ยนแปลงของปริมาณที่วัด ซึ่งช่วยให้การประมวลผลสัญญาณง่ายขึ้น อย่างไรก็ตาม ควรทราบว่าความไวสูงอาจทำให้เกิดเสียงรบกวนจากภายนอกที่ไม่เกี่ยวข้องกับปริมาณที่วัดได้ง่าย และเสียงรบกวนนี้สามารถถูกขยายโดยระบบและส่งผลกระทบต่อความแม่นยำของการวัด ดังนั้น เซนเซอร์เองควรมีอัตราส่วนสัญญาณต่อเสียงรบกวนสูงเพื่อลดการรบกวนจากแหล่งภายนอก

ความไวของเซนเซอร์มีทิศทาง หากต้องการวัดในทิศทางเดียวที่มีข้อกำหนดเรื่องทิศทางสูง ให้เลือกเซนเซอร์ที่มีความไวต่ำในทิศทางอื่น ๆ ส่วนสำหรับการวัดหลายมิติ ให้เลือกเซนเซอร์ที่มีความไวไขว้น้อยที่สุด

T สาม, r ลักษณะการตอบสนอง (เวลาในการตอบสนอง) . ลักษณะการตอบสนองความถี่ของเซนเซอร์เป็นตัวกำหนดช่วงความถี่ที่สามารถวัดได้ของปริมาณที่วัด โดยต้องรักษาการวัดที่ไม่บิดเบือนภายในช่วงความถี่ที่ยอมให้ได้ ในทางปฏิบัติ การตอบสนองของเซนเซอร์จะมีความล่าช้าอยู่เสมอ และควรเลือกใช้เซนเซอร์ที่มีเวลาหน่วงสั้นกว่า ยิ่งการตอบสนองความถี่สูงขึ้นเท่าใด ก็ยิ่งสามารถวัดสัญญาณในช่วงความถี่ที่กว้างขึ้นได้ ในขณะที่ระบบกลไกที่มีความเฉื่อยมาก (เนื่องจากข้อจำกัดของโครงสร้าง) เหมาะกับเซนเซอร์ที่มีความถี่ธรรมชาติต่ำและช่วงความถี่ที่วัดได้แคบลง ในการวัดแบบไดนามิก ควรจับคู่ลักษณะการตอบสนองให้สอดคล้องกับประเภทของสัญญาณ (คงที่ ชั่วคราว สุ่ม เป็นต้น) เพื่อหลีกเลี่ยงข้อผิดพลาดที่เกินขนาด

ข้อสี่ ช่วงเชิงเส้น . ช่วงเชิงเส้นของเซนเซอร์หมายถึงช่วงที่ค่าเอาต์พุตเป็นสัดส่วนกับค่าอินพุต ทางทฤษฎีแล้วความไวจะคงที่ภายในช่วงนี้ การมีช่วงเชิงเส้นที่กว้างขึ้นจะทำให้มีช่วงการวัดที่มากขึ้นและรับประกันความแม่นยำของการวัด เมื่อเลือกใช้เซนเซอร์ ควรตรวจสอบก่อนว่าช่วงของเซนเซอร์นั้นตรงตามความต้องการหรือไม่หลังจากกำหนดประเภทของเซนเซอร์แล้ว

ในทางปฏิบัติ เซนเซอร์ไม่มีตัวใดที่เป็นเชิงเส้นอย่างสมบูรณ์ และความเป็นเชิงเส้นเป็นเพียงสัมพัทธ์ สำหรับความต้องการในการวัดที่มีความแม่นยำต่ำ เซนเซอร์ที่มีความคลาดเคลื่อนแบบไม่เชิงเส้นเล็กน้อยสามารถประมาณได้ว่าเป็นเชิงเส้นภายในช่วงหนึ่ง ซึ่งช่วยลดความซับซ้อนของการวัดลงอย่างมาก

F ข้อห้า ความคงที่ . ความเสถียรหมายถึงความสามารถของเซนเซอร์ในการรักษาประสิทธิภาพเดิมโดยไม่เปลี่ยนแปลงหลังจากการใช้งานเป็นระยะเวลาหนึ่ง ปัจจัยที่ส่งผลต่อความเสถียรระยะยาวไม่ได้เกิดจากโครงสร้างของเซนเซอร์เพียงอย่างเดียว แต่ยังรวมถึงสภาพแวดล้อมในการทำงานด้วย ดังนั้น เพื่อรับรองความเสถียรที่ดี เซนเซอร์จำเป็นต้องมีความสามารถในการปรับตัวต่อสภาพแวดล้อมที่ดี

ก่อนเลือกเซนเซอร์ ควรตรวจสอบสภาพแวดล้อมที่ตั้งใจจะใช้งาน และเลือกเซนเซอร์ที่เหมาะสม หรือดำเนินการเพื่อลดผลกระทบจากสิ่งแวดล้อม เสถียรภาพมีตัวชี้วัดเชิงปริมาณ; หลังจากเกินอายุการใช้งานแล้ว ควรสอบเทียบเซนเซอร์ใหม่ก่อนใช้งาน เพื่อยืนยันว่าประสิทธิภาพยังคงเดิมหรือไม่ -ในแอปพลิเคชันที่ต้องใช้งานระยะยาวโดยไม่สามารถเปลี่ยนหรือสอบเทียบใหม่ได้ง่าย ข้อกำหนดด้านความเสถียรของเซนเซอร์จะเข้มงวดมากขึ้น จำเป็นต้องทนต่อการทดสอบในระยะเวลานาน -ข้อหก

S ความแม่นยำเป็นตัวชี้วัดประสิทธิภาพที่สำคัญของเซนเซอร์ และเป็นปัจจัยหลักที่ส่งผลต่อความแม่นยำของการวัดทั้งระบบ เซนเซอร์ที่มีความแม่นยำสูงจะมีราคาแพงกว่า ดังนั้นความแม่นยำของเซนเซอร์ควรเพียงพอต่อความต้องการของระบบเท่านั้น—ไม่จำเป็นต้องสูงเกินไป ซึ่งจะทำให้สามารถเลือกเซนเซอร์ที่ถูกกว่าและเรียบง่ายกว่าได้ในกลุ่มที่ตอบสนองวัตถุประสงค์การวัดเดียวกัน ความแม่นยำ . สำหรับการวิเคราะห์เชิงคุณภาพ ควรเลือกเซนเซอร์ที่มีความซ้ำซ้อนสูง แทนที่จะเน้นความแม่นยำสัมบูรณ์สูง สำหรับการวิเคราะห์เชิงคุณภาพ ให้เลือกเซนเซอร์ที่มีความซ้ำซ้อนสูง แทนที่จะเป็นความแม่นยำสัมบูรณ์สูง สำหรับการวิเคราะห์เชิงปริมาณที่ต้องการการวัดค่าอย่างแม่นยำ ให้เลือกเซนเซอร์ที่มีเกรดความแม่นยำเหมาะสม

ในกรณีพิเศษที่ไม่มีเซนเซอร์ที่เหมาะสมสำหรับใช้งาน อาจจำเป็นต้องออกแบบและผลิตเอง โดยเซนเซอร์ที่ทำขึ้นเองนั้นต้องตอบสนองตามข้อกำหนดด้านสมรรถนะ

ข่าวเด่น

ข่าวเด่น2025-11-21

2025-11-13

2025-11-13

2025-10-29

2025-10-22

2025-10-28